国家标准GB3098.13(点击下载)中规定了8.8级 9.8级 10.9级 12.9级螺丝的部分规格的最小破坏扭矩(出于方便理解下称扭力吧),其核心内容有两点:

-

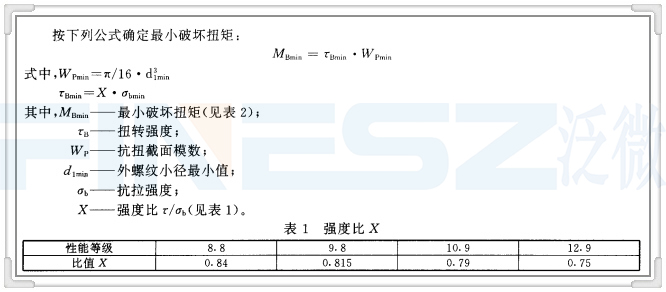

扭力的计算方法:

重点:扭力=抗拉强度*强度比*截面抗扭模数

其中,抗拉强度σb在GB3098.1(点此下载GB/T3098.1-2010.PDF文档)有规定,强度比X在GB3098.13中有规定,抗扭截面模数WP是一个材料力学概念,公式是固定的即3.14/16*d3。有了这个计算方法,基本可以获取所有级别螺丝的扭力参数。

-

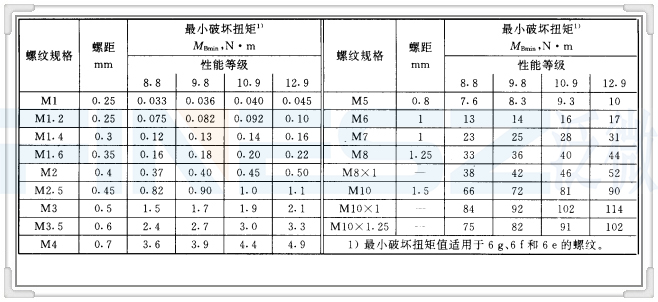

GB3098.13提供常用规格的扭力参考数据:

以上两点本身没毛病,但是在查阅使用过程中着实让人很D疼,1是公式太魅涩,看起来瘆的慌;2是表格没卵用,样本太少。

出于日常查阅方便,现将所有螺丝的扭力的计算值列表如下,其中公制螺丝部分按GB3098.13计算,美制螺丝部分按ASTM F606/606M(并结合GB3098.13)计算。为方便直觉体会,美制螺丝扭力也采用牛米NM为单位。

值得说明的是,标准中对于被测试物有一些前置要求,比如不适用于M10以上、不适用于紧定等等,这些就不管它了,本表提供的是理论计算值。

公制部分。4.8级、8.8级、9.8级、10.9级、12.9级螺丝的扭力- 4.8级螺丝扭力标准:

感谢评论区 @狗蛋的建议,以下4.8级强度比系数取值按X=0.916:

| 螺纹 规格 |

外径 (mm) |

牙距 (mm) |

牙底径 (mm) |

4.8抗拉强度 (Mpa) |

强度比(鼠标停见说明) | 扭转强度 (Mpa) |

抗扭截面模数 | 理论扭力 (NM) |

扭力国标值 (NM) |

相差 (NM) |

建议安装力 (NM) |

| D | P | d | σb min | X | τB | WP | MB | S | |||

| M1*0.25 | 0.93 | 0.25 | 0.6594 | 420 | 0.916 | 384.72 | 0.06 | 0.022 | 未规定 | 0.013 | |

| M1.2*0.25 | 1.13 | 0.25 | 0.8594 | 420 | 0.916 | 384.72 | 0.12 | 0.048 | 0.029 | ||

| M1.4*0.3 | 1.33 | 0.3 | 1.0052 | 420 | 0.916 | 384.72 | 0.20 | 0.077 | 0.046 | ||

| M1.6*0.35 | 1.5 | 0.35 | 1.1211 | 420 | 0.916 | 384.72 | 0.28 | 0.106 | 0.064 | ||

| M2*0.4 | 1.89 | 0.4 | 1.4570 | 420 | 0.916 | 384.72 | 0.61 | 0.234 | 0.14 | ||

| M2.5*0.45 | 2.38 | 0.45 | 1.8929 | 420 | 0.916 | 384.72 | 1.33 | 0.51 | 0.31 | ||

| M3*0.5 | 2.87 | 0.5 | 2.3287 | 420 | 0.916 | 384.72 | 2.48 | 0.95 | 0.57 | ||

| M3.5*0.6 | 3.35 | 0.6 | 2.7005 | 420 | 0.916 | 384.72 | 3.86 | 1.49 | 0.89 | ||

| M4*0.7 | 3.84 | 0.7 | 3.0822 | 420 | 0.916 | 384.72 | 5.75 | 2.21 | 1.33 | ||

| M5*0.8 | 4.83 | 0.8 | 3.9640 | 420 | 0.916 | 384.72 | 12.22 | 4.70 | 2.82 | ||

| M6*1.0 | 5.79 | 1 | 4.7075 | 420 | 0.916 | 384.72 | 20.47 | 7.88 | 4.73 | ||

| M8*1.25 | 7.76 | 1.25 | 6.4069 | 420 | 0.916 | 384.72 | 51.61 | 19.86 | 11.91 | ||

| M10*1.5 | 9.73 | 1.5 | 8.1062 | 420 | 0.916 | 384.72 | 104.54 | 40.22 | 24.13 | ||

| M12*1.75 | 11.7 | 1.75 | 9.8056 | 420 | 0.916 | 384.72 | 185.03 | 71.18 | 42.71 | ||

| M14*1.75 | 13.68 | 1.75 | 11.7856 | 420 | 0.916 | 384.72 | 321.27 | 123.60 | 74.16 | ||

| M16*2 | 15.68 | 2 | 13.5150 | 420 | 0.916 | 384.72 | 484.46 | 186.38 | 111.83 | ||

| M18*2 | 17.62 | 2 | 15.4550 | 420 | 0.916 | 384.72 | 724.46 | 278.71 | 167.23 | ||

| M20*2.5 | 19.62 | 2.5 | 16.9137 | 420 | 0.916 | 384.72 | 949.57 | 365.32 | 219.19 | ||

| M22*2.5 | 21.62 | 2.5 | 18.9137 | 420 | 0.916 | 384.72 | 1327.82 | 510.84 | 306.50 | ||

| M24*3 | 23.58 | 3 | 20.3324 | 420 | 0.916 | 384.72 | 1649.60 | 634.63 | 380.78 | ||

| M27*3 | 26.58 | 3 | 23.3324 | 420 | 0.916 | 384.72 | 2492.82 | 959.04 | 575.42 | ||

| M30*3.5 | 29.52 | 3.5 | 25.7312 | 420 | 0.916 | 384.72 | 3343.40 | 1286.27 | 771.76 | ||

| M33*3.5 | 32.52 | 3.5 | 28.7312 | 420 | 0.916 | 384.72 | 4654.47 | 1790.67 | 1074.40 | ||

| M36*4 | 35.47 | 4 | 31.1399 | 420 | 0.916 | 384.72 | 5926.01 | 2279.85 | 1367.91 | ||

| M39*4 | 38.47 | 4 | 34.1399 | 420 | 0.916 | 384.72 | 7809.03 | 3004.29 | 1802.57 |

- 8.8级螺丝扭力标准:

| 螺纹 规格 |

外径 (mm) |

牙距 (mm) |

牙底径 (mm) |

8.8抗拉强度 (Mpa) |

强度比 | 扭转强度 (Mpa) |

抗扭截面模数 | 理论扭力 (NM) |

扭力国标值 (NM) |

相差 (NM) |

建议安装力 (NM) |

| D | P | d | σb min | X | τB | WP | MB | S | |||

| M1*0.25 | 0.93 | 0.25 | 0.6594 | 800 | 0.84 | 672 | 0.06 | 0.038 | 0.033 | 0.005 | 0.023 |

| M1.2*0.25 | 1.13 | 0.25 | 0.8594 | 800 | 0.84 | 672 | 0.12 | 0.084 | 0.075 | 0.009 | 0.050 |

| M1.4*0.3 | 1.34 | 0.3 | 1.0152 | 800 | 0.84 | 672 | 0.21 | 0.138 | 0.12 | 0.018 | 0.083 |

| M1.6*0.35 | 1.5 | 0.35 | 1.1211 | 800 | 0.84 | 672 | 0.28 | 0.186 | 0.16 | 0.026 | 0.112 |

| M2*0.4 | 1.89 | 0.4 | 1.4570 | 800 | 0.84 | 672 | 0.61 | 0.41 | 0.37 | 0.038 | 0.24 |

| M2.5*0.45 | 2.38 | 0.45 | 1.8929 | 800 | 0.84 | 672 | 1.33 | 0.89 | 0.82 | 0.074 | 0.54 |

| M3*0.5 | 2.88 | 0.5 | 2.3387 | 800 | 0.84 | 672 | 2.51 | 1.69 | 1.5 | 0.19 | 1.01 |

| M3.5*0.6 | 3.36 | 0.6 | 2.7105 | 800 | 0.84 | 672 | 3.91 | 2.63 | 2.4 | 0.23 | 1.58 |

| M4*0.7 | 3.83 | 0.7 | 3.0722 | 800 | 0.84 | 672 | 5.69 | 3.82 | 3.6 | 0.22 | 2.29 |

| M5*0.8 | 4.78 | 0.8 | 3.9140 | 800 | 0.84 | 672 | 11.77 | 7.91 | 7.6 | 0.31 | 4.74 |

| M6*1.0 | 5.78 | 1 | 4.6975 | 800 | 0.84 | 672 | 20.34 | 13.67 | 13 | 0.67 | 8.20 |

| M8*1.25 | 7.78 | 1.25 | 6.4269 | 800 | 0.84 | 672 | 52.10 | 35.01 | 33 | 2.01 | 21.01 |

| M10*1.5 | 9.77 | 1.5 | 8.1462 | 800 | 0.84 | 672 | 106.09 | 71.29 | 66 | 5.29 | 42.78 |

| M12*1.75 | 11.76 | 1.75 | 9.8656 | 800 | 0.84 | 672 | 188.44 | 126.63 | 没规定 | 75.98 | |

| M14*1.75 | 13.74 | 1.75 | 11.8456 | 800 | 0.84 | 672 | 326.20 | 219.20 | 131.52 | ||

| M16*2 | 15.74 | 2 | 13.5750 | 800 | 0.84 | 672 | 490.94 | 329.91 | 197.95 | ||

| M18*2 | 17.71 | 2 | 15.5450 | 830 | 0.84 | 697.2 | 737.19 | 513.97 | 308.38 | ||

| M20*2.5 | 19.71 | 2.5 | 17.0037 | 830 | 0.84 | 697.2 | 964.81 | 672.66 | 403.60 | ||

| M22*2.5 | 21.62 | 2.5 | 18.9137 | 830 | 0.84 | 697.2 | 1327.82 | 925.76 | 555.45 | ||

| M24*3 | 23.58 | 3 | 20.3324 | 830 | 0.84 | 697.2 | 1649.60 | 1150.10 | 690.06 | ||

| M27*3 | 26.58 | 3 | 23.3324 | 830 | 0.84 | 697.2 | 2492.82 | 1737.99 | 1042.79 | ||

| M30*3.5 | 29.52 | 3.5 | 25.7312 | 830 | 0.84 | 697.2 | 3343.40 | 2331.02 | 1398.61 | ||

| M33*3.5 | 32.52 | 3.5 | 28.7312 | 830 | 0.84 | 697.2 | 4654.47 | 3245.10 | 1947.06 | ||

| M36*4 | 35.47 | 4 | 31.1399 | 830 | 0.84 | 697.2 | 5926.01 | 4131.61 | 2478.97 | ||

| M39*4 | 38.47 | 4 | 34.1399 | 830 | 0.84 | 697.2 | 7809.03 | 5444.46 | 3266.67 |

- 9.8级螺丝扭力标准:

| 螺纹 规格 |

外径 (mm) |

牙距 (mm) |

牙底径 (mm) |

9.8抗拉强度 (Mpa) |

强度比 | 扭转强度 (Mpa) |

抗扭截面模数 | 理论扭力 (NM) |

扭力国标值 (NM) |

相差 (NM) |

建议安装力 (NM) |

| D | P | d | σb min | X | τB | WP | MB | S | |||

| M1*0.25 | 0.93 | 0.25 | 0.6594 | 900 | 0.815 | 733.5 | 0.06 | 0.041 | 0.036 | 0.005 | 0.025 |

| M1.2*0.25 | 1.13 | 0.25 | 0.8594 | 900 | 0.815 | 733.5 | 0.12 | 0.091 | 0.082 | 0.009 | 0.055 |

| M1.4*0.3 | 1.34 | 0.3 | 1.0152 | 900 | 0.815 | 733.5 | 0.21 | 0.151 | 0.13 | 0.021 | 0.090 |

| M1.6*0.35 | 1.5 | 0.35 | 1.1211 | 900 | 0.815 | 733.5 | 0.28 | 0.203 | 0.18 | 0.023 | 0.122 |

| M2*0.4 | 1.89 | 0.4 | 1.4570 | 900 | 0.815 | 733.5 | 0.61 | 0.45 | 0.40 | 0.045 | 0.267 |

| M2.5*0.45 | 2.38 | 0.45 | 1.8929 | 900 | 0.815 | 733.5 | 1.33 | 0.98 | 0.9 | 0.08 | 0.59 |

| M3*0.5 | 2.88 | 0.5 | 2.3387 | 900 | 0.815 | 733.5 | 2.51 | 1.84 | 1.7 | 0.14 | 1.10 |

| M3.5*0.6 | 3.36 | 0.6 | 2.7105 | 900 | 0.815 | 733.5 | 3.91 | 2.87 | 2.7 | 0.17 | 1.72 |

| M4*0.7 | 3.83 | 0.7 | 3.0722 | 900 | 0.815 | 733.5 | 5.69 | 4.17 | 3.9 | 0.27 | 2.50 |

| M5*0.8 | 4.78 | 0.8 | 3.9140 | 900 | 0.815 | 733.5 | 11.77 | 8.63 | 8.3 | 0.33 | 5.18 |

| M6*1.0 | 5.78 | 1 | 4.6975 | 900 | 0.815 | 733.5 | 20.34 | 14.92 | 14 | 0.92 | 8.95 |

| M8*1.25 | 7.78 | 1.25 | 6.4269 | 900 | 0.815 | 733.5 | 52.10 | 38.21 | 36 | 2.21 | 22.93 |

| M10*1.5 | 9.77 | 1.5 | 8.1462 | 900 | 0.815 | 733.5 | 106.09 | 77.82 | 72 | 5.82 | 46.69 |

| M12*1.75 | 11.76 | 1.75 | 9.8656 | 900 | 0.815 | 733.5 | 188.44 | 138.22 | 没规定 | 82.93 | |

| M14*1.75 | 13.74 | 1.75 | 11.8456 | 900 | 0.815 | 733.5 | 326.20 | 239.27 | 143.56 | ||

| M16*2 | 15.74 | 2 | 13.5750 | 900 | 0.815 | 733.5 | 490.94 | 360.10 | 216.06 | ||

| M18*2 | 17.71 | 2 | 15.5450 | 900 | 0.815 | 733.5 | 737.19 | 540.73 | 324.44 | ||

| M20*2.5 | 19.71 | 2.5 | 17.0037 | 900 | 0.815 | 733.5 | 964.81 | 707.69 | 424.61 | ||

| M22*2.5 | 21.62 | 2.5 | 18.9137 | 900 | 0.815 | 733.5 | 1327.82 | 973.96 | 584.37 | ||

| M24*3 | 23.58 | 3 | 20.3324 | 900 | 0.815 | 733.5 | 1649.60 | 1209.98 | 725.99 | ||

| M27*3 | 26.58 | 3 | 23.3324 | 900 | 0.815 | 733.5 | 2492.82 | 1828.48 | 1097.09 | ||

| M30*3.5 | 29.52 | 3.5 | 25.7312 | 900 | 0.815 | 733.5 | 3343.40 | 2452.39 | 1471.43 | ||

| M33*3.5 | 32.52 | 3.5 | 28.7312 | 900 | 0.815 | 733.5 | 4654.47 | 3414.05 | 2048.43 | ||

| M36*4 | 35.47 | 4 | 31.1399 | 900 | 0.815 | 733.5 | 5926.01 | 4346.73 | 2608.04 | ||

| M39*4 | 38.47 | 4 | 34.1399 | 900 | 0.815 | 733.5 | 7809.03 | 5727.92 | 3436.75 |

- 10.9级螺丝扭力标准:

| 螺纹 规格 |

外径 (mm) |

牙距 (mm) |

牙底径 (mm) |

10.9抗拉强度 (Mpa) |

强度比 | 扭转强度 (Mpa) |

抗扭截面模数 | 理论扭力 (NM) |

扭力国标值 (NM) |

相差 (NM) |

建议安装力 (NM) |

| D | P | d | σb min | X | τB | WP | MB | S | |||

| M1*0.25 | 0.93 | 0.25 | 0.6594 | 1040 | 0.79 | 821.6 | 0.06 | 0.046 | 0.040 | 0.006 | 0.028 |

| M1.2*0.25 | 1.13 | 0.25 | 0.8594 | 1040 | 0.79 | 821.6 | 0.12 | 0.102 | 0.092 | 0.010 | 0.061 |

| M1.4*0.3 | 1.34 | 0.3 | 1.0152 | 1040 | 0.79 | 821.6 | 0.21 | 0.169 | 0.14 | 0.029 | 0.101 |

| M1.6*0.35 | 1.5 | 0.35 | 1.1211 | 1040 | 0.79 | 821.6 | 0.28 | 0.227 | 0.20 | 0.027 | 0.136 |

| M2*0.4 | 1.89 | 0.4 | 1.4570 | 1040 | 0.79 | 821.6 | 0.61 | 0.50 | 0.45 | 0.049 | 0.299 |

| M2.5*0.45 | 2.38 | 0.45 | 1.8929 | 1040 | 0.79 | 821.6 | 1.33 | 1.09 | 1 | 0.09 | 0.66 |

| M3*0.5 | 2.88 | 0.5 | 2.3387 | 1040 | 0.79 | 821.6 | 2.51 | 2.06 | 1.9 | 0.16 | 1.24 |

| M3.5*0.6 | 3.36 | 0.6 | 2.7105 | 1040 | 0.79 | 821.6 | 3.91 | 3.21 | 3 | 0.21 | 1.93 |

| M4*0.7 | 3.83 | 0.7 | 3.0722 | 1040 | 0.79 | 821.6 | 5.69 | 4.68 | 4.4 | 0.28 | 2.81 |

| M5*0.8 | 4.78 | 0.8 | 3.9140 | 1040 | 0.79 | 821.6 | 11.77 | 9.67 | 9.3 | 0.37 | 5.80 |

| M6*1.0 | 5.78 | 1 | 4.6975 | 1040 | 0.79 | 821.6 | 20.34 | 16.71 | 16 | 0.71 | 10.03 |

| M8*1.25 | 7.78 | 1.25 | 6.4269 | 1040 | 0.79 | 821.6 | 52.10 | 42.80 | 40 | 2.80 | 25.68 |

| M10*1.5 | 9.77 | 1.5 | 8.1462 | 1040 | 0.79 | 821.6 | 106.09 | 87.16 | 81 | 6.16 | 52.30 |

| M12*1.75 | 11.76 | 1.75 | 9.8656 | 1040 | 0.79 | 821.6 | 188.44 | 154.82 | 没规定 | 92.89 | |

| M14*1.75 | 13.74 | 1.75 | 11.8456 | 1040 | 0.79 | 821.6 | 326.20 | 268.00 | 160.80 | ||

| M16*2 | 15.74 | 2 | 13.5750 | 1040 | 0.79 | 821.6 | 490.94 | 403.35 | 242.01 | ||

| M18*2 | 17.71 | 2 | 15.5450 | 1040 | 0.79 | 821.6 | 737.19 | 605.67 | 363.40 | ||

| M20*2.5 | 19.71 | 2.5 | 17.0037 | 1040 | 0.79 | 821.6 | 964.81 | 792.68 | 475.61 | ||

| M22*2.5 | 21.62 | 2.5 | 18.9137 | 1040 | 0.79 | 821.6 | 1327.82 | 1090.94 | 654.56 | ||

| M24*3 | 23.58 | 3 | 20.3324 | 1040 | 0.79 | 821.6 | 1649.60 | 1355.31 | 813.19 | ||

| M27*3 | 26.58 | 3 | 23.3324 | 1040 | 0.79 | 821.6 | 2492.82 | 2048.10 | 1228.86 | ||

| M30*3.5 | 29.52 | 3.5 | 25.7312 | 1040 | 0.79 | 821.6 | 3343.40 | 2746.94 | 1648.16 | ||

| M33*3.5 | 32.52 | 3.5 | 28.7312 | 1040 | 0.79 | 821.6 | 4654.47 | 3824.11 | 2294.47 | ||

| M36*4 | 35.47 | 4 | 31.1399 | 1040 | 0.79 | 821.6 | 5926.01 | 4868.81 | 2921.28 | ||

| M39*4 | 38.47 | 4 | 34.1399 | 1040 | 0.79 | 821.6 | 7809.03 | 6415.90 | 3849.54 |

- 12.9级螺丝扭力标准:

| 螺纹 规格 |

外径 (mm) |

牙距 (mm) |

牙底径 (mm) |

12.9抗拉强度 (Mpa) |

强度比 | 扭转强度 (Mpa) |

抗扭截面模数 | 理论扭力 (NM) |

扭力国标值 (NM) |

相差 (NM) |

建议安装力 (NM) |

| D | P | d | σb min | X | τB | WP | MB | S | |||

| M1*0.25 | 0.93 | 0.25 | 0.6594 | 1220 | 0.75 | 915 | 0.06 | 0.05 | 0.045 | 0.006 | 0.031 |

| M1.2*0.25 | 1.13 | 0.25 | 0.8594 | 1220 | 0.75 | 915 | 0.12 | 0.11 | 0.10 | 0.014 | 0.068 |

| M1.4*0.3 | 1.34 | 0.3 | 1.0152 | 1220 | 0.75 | 915 | 0.21 | 0.19 | 0.16 | 0.028 | 0.113 |

| M1.6*0.35 | 1.5 | 0.35 | 1.1211 | 1220 | 0.75 | 915 | 0.28 | 0.25 | 0.22 | 0.033 | 0.152 |

| M2*0.4 | 1.89 | 0.4 | 1.4570 | 1220 | 0.75 | 915 | 0.61 | 0.56 | 0.50 | 0.055 | 0.333 |

| M2.5*0.45 | 2.38 | 0.45 | 1.8929 | 1220 | 0.75 | 915 | 1.33 | 1.22 | 1.1 | 0.12 | 0.73 |

| M3*0.5 | 2.88 | 0.5 | 2.3387 | 1220 | 0.75 | 915 | 2.51 | 2.30 | 2.1 | 0.20 | 1.38 |

| M3.5*0.6 | 3.36 | 0.6 | 2.7105 | 1220 | 0.75 | 915 | 3.91 | 3.58 | 3.3 | 0.28 | 2.15 |

| M4*0.7 | 3.83 | 0.7 | 3.0722 | 1220 | 0.75 | 915 | 5.69 | 5.21 | 4.9 | 0.31 | 3.12 |

| M5*0.8 | 4.78 | 0.8 | 3.9140 | 1220 | 0.75 | 915 | 11.77 | 10.77 | 10 | 0.77 | 6.46 |

| M6*1.0 | 5.78 | 1 | 4.6975 | 1220 | 0.75 | 915 | 20.34 | 18.61 | 17 | 1.61 | 11.17 |

| M8*1.25 | 7.78 | 1.25 | 6.4269 | 1220 | 0.75 | 915 | 52.10 | 47.67 | 44 | 3.67 | 28.60 |

| M10*1.5 | 9.77 | 1.5 | 8.1462 | 1220 | 0.75 | 915 | 106.09 | 97.07 | 90 | 7.07 | 58.24 |

| M12*1.75 | 11.76 | 1.75 | 9.8656 | 1220 | 0.75 | 915 | 188.44 | 172.42 | 没规定 | 103.45 | |

| M14*1.75 | 13.74 | 1.75 | 11.8456 | 1220 | 0.75 | 915 | 326.20 | 298.47 | 179.08 | ||

| M16*2 | 15.74 | 2 | 13.5750 | 1220 | 0.75 | 915 | 490.94 | 449.21 | 269.52 | ||

| M18*2 | 17.71 | 2 | 15.5450 | 1220 | 0.75 | 915 | 737.19 | 674.53 | 404.72 | ||

| M20*2.5 | 19.71 | 2.5 | 17.0037 | 1220 | 0.75 | 915 | 964.81 | 882.80 | 529.68 | ||

| M22*2.5 | 21.62 | 2.5 | 18.9137 | 1220 | 0.75 | 915 | 1327.82 | 1214.96 | 728.97 | ||

| M24*3 | 23.58 | 3 | 20.3324 | 1220 | 0.75 | 915 | 1649.60 | 1509.38 | 905.63 | ||

| M27*3 | 26.58 | 3 | 23.3324 | 1220 | 0.75 | 915 | 2492.82 | 2280.93 | 1368.56 | ||

| M30*3.5 | 29.52 | 3.5 | 25.7312 | 1220 | 0.75 | 915 | 3343.40 | 3059.21 | 1835.53 | ||

| M33*3.5 | 32.52 | 3.5 | 28.7312 | 1220 | 0.75 | 915 | 4654.47 | 4258.84 | 2555.30 | ||

| M36*4 | 35.47 | 4 | 31.1399 | 1220 | 0.75 | 915 | 5926.01 | 5422.30 | 3253.38 | ||

| M39*4 | 38.47 | 4 | 34.1399 | 1220 | 0.75 | 915 | 7809.03 | 7145.26 | 4287.16 |

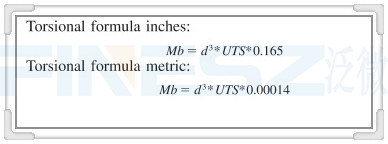

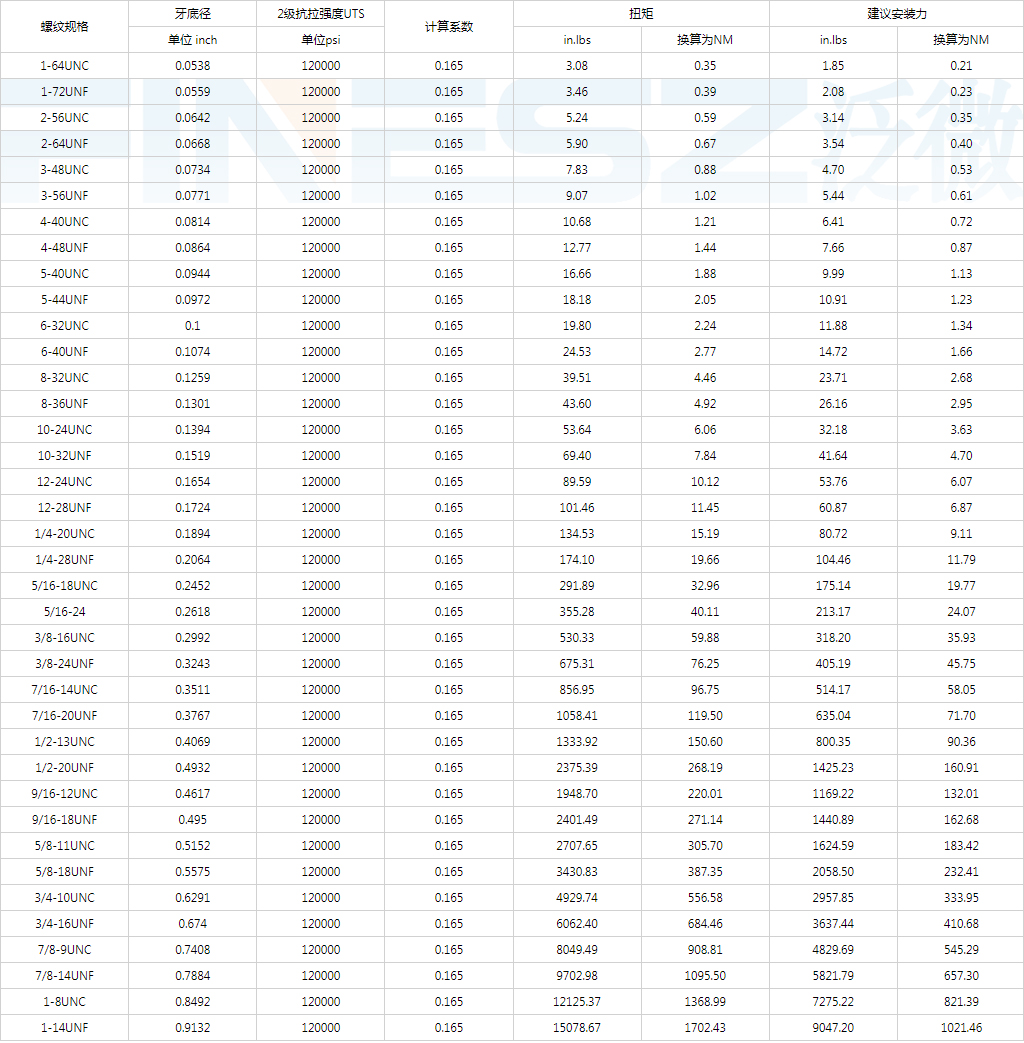

美制螺丝的扭力标准来自ASTM F606/606M,标准给出的扭力计算公式如下:

即:![]()

扭矩Mb(以美制为单位)=d3*抗拉强度UTS*0.165

扭矩Mb(以公制为单位)=d3*抗拉强度UTS*0.00014

![]()

其中第二条关于公制螺丝计算公式等效于本文上面所述的GB3098.13公式,甚至还更精准一些,为避免重复,下面只计算美制螺丝部分。

以美制5级1/4-20UNC公差等级2A的螺丝为例:

1/4-20UNC螺丝的牙底径:0.1894inch (数据来源:螺纹的大径中径小径表,请自行换算一下公、英制关系)

1/4*20UNC 5级的抗拉强度UTS:120000psi (标准来源:SAE J429,点击下载SAE J429-1999.PDF标准,文档中第3页)

故:

Mb=0.18943*12000*0.165=134.53 in.lbs![]()

我们将所有规格、等级的美制螺丝扭矩标准列表如下,如前所述,这些参数基本于理论计算值 ,且忽略掉了一些前置条件,如不适用于螺柱、一字螺钉,十字槽螺钉、螺纹不能小于1/4或大于1寸、螺栓不能超级长…等等,总之你懂的就行。

- 美制2级螺丝扭力标准(精度2A):

| 螺纹规格 | 牙底径 | 2级抗拉强度UTS | 计算系数 | 扭矩 | 建议安装力 | ||

| inch-牙数 | 单位 inch | 单位psi | in.lbs | 换算为NM | in.lbs | 换算为NM | |

| 1-64UNC | 0.0538 | 74000 | 0.165 | 1.90 | 0.21 | 1.14 | 0.13 |

| 1-72UNF | 0.0559 | 74000 | 0.165 | 2.13 | 0.24 | 1.28 | 0.14 |

| 2-56UNC | 0.0642 | 74000 | 0.165 | 3.23 | 0.36 | 1.94 | 0.22 |

| 2-64UNF | 0.0668 | 74000 | 0.165 | 3.64 | 0.41 | 2.18 | 0.25 |

| 3-48UNC | 0.0734 | 74000 | 0.165 | 4.83 | 0.55 | 2.90 | 0.33 |

| 3-56UNF | 0.0771 | 74000 | 0.165 | 5.60 | 0.63 | 3.36 | 0.38 |

| 4-40UNC | 0.0814 | 74000 | 0.165 | 6.59 | 0.74 | 3.95 | 0.45 |

| 4-48UNF | 0.0864 | 74000 | 0.165 | 7.88 | 0.89 | 4.73 | 0.53 |

| 5-40UNC | 0.0944 | 74000 | 0.165 | 10.27 | 1.16 | 6.16 | 0.70 |

| 5-44UNF | 0.0972 | 74000 | 0.165 | 11.21 | 1.27 | 6.73 | 0.76 |

| 6-32UNC | 0.1 | 74000 | 0.165 | 12.21 | 1.38 | 7.33 | 0.83 |

| 6-40UNF | 0.1074 | 74000 | 0.165 | 15.13 | 1.71 | 9.08 | 1.02 |

| 8-32UNC | 0.1259 | 74000 | 0.165 | 24.37 | 2.75 | 14.62 | 1.65 |

| 8-36UNF | 0.1301 | 74000 | 0.165 | 26.89 | 3.04 | 16.13 | 1.82 |

| 10-24UNC | 0.1394 | 74000 | 0.165 | 33.08 | 3.73 | 19.85 | 2.24 |

| 10-32UNF | 0.1519 | 74000 | 0.165 | 42.79 | 4.83 | 25.68 | 2.90 |

| 12-24UNC | 0.1654 | 74000 | 0.165 | 55.25 | 6.24 | 33.15 | 3.74 |

| 12-28UNF | 0.1724 | 74000 | 0.165 | 62.56 | 7.06 | 37.54 | 4.24 |

| 1/4-20UNC | 0.1894 | 74000 | 0.165 | 82.96 | 9.37 | 49.77 | 5.62 |

| 1/4-28UNF | 0.2064 | 74000 | 0.165 | 107.36 | 12.12 | 64.42 | 7.27 |

| 5/16-18UNC | 0.2452 | 74000 | 0.165 | 180.00 | 20.32 | 108.00 | 12.19 |

| 5/16-24 | 0.2618 | 74000 | 0.165 | 219.09 | 24.74 | 131.45 | 14.84 |

| 3/8-16UNC | 0.2992 | 74000 | 0.165 | 327.04 | 36.92 | 196.22 | 22.15 |

| 3/8-24UNF | 0.3243 | 74000 | 0.165 | 416.44 | 47.02 | 249.87 | 28.21 |

| 7/16-14UNC | 0.3511 | 74000 | 0.165 | 528.46 | 59.66 | 317.07 | 35.80 |

| 7/16-20UNF | 0.3767 | 74000 | 0.165 | 652.68 | 73.69 | 391.61 | 44.21 |

| 1/2-13UNC | 0.4069 | 74000 | 0.165 | 822.58 | 92.87 | 493.55 | 55.72 |

| 1/2-20UNF | 0.4932 | 74000 | 0.165 | 1464.82 | 165.38 | 878.89 | 99.23 |

| 9/16-12UNC | 0.4617 | 74000 | 0.165 | 1201.70 | 135.68 | 721.02 | 81.41 |

| 9/16-18UNF | 0.495 | 74000 | 0.165 | 1480.92 | 167.20 | 888.55 | 100.32 |

| 5/8-11UNC | 0.5152 | 74000 | 0.165 | 1669.72 | 188.52 | 1001.83 | 113.11 |

| 5/8-18UNF | 0.5575 | 74000 | 0.165 | 2115.68 | 238.87 | 1269.41 | 143.32 |

| 3/4-10UNC | 0.6291 | 74000 | 0.165 | 3040.01 | 343.23 | 1824.00 | 205.94 |

| 3/4-16UNF | 0.674 | 74000 | 0.165 | 3738.48 | 422.09 | 2243.09 | 253.25 |

| 7/8-9UNC | 0.7408 | 74000 | 0.165 | 4963.85 | 560.43 | 2978.31 | 336.26 |

| 7/8-14UNF | 0.7884 | 74000 | 0.165 | 5983.50 | 675.56 | 3590.10 | 405.33 |

| 1-8UNC | 0.8492 | 74000 | 0.165 | 7477.31 | 844.21 | 4486.39 | 506.53 |

| 1-14UNF | 0.9132 | 74000 | 0.165 | 9298.51 | 1049.83 | 5579.11 | 629.90 |

- 美制5级螺栓扭力标准(精度2A):

- 美制8级螺栓扭力标准(精度2A):

| 螺纹规格 | 牙底径 | 8级抗拉强度UTS | 计算系数 | 扭矩 | 建议安装力 | ||

| 单位 inch | 单位psi | in.lbs | 换算为NM | in.lbs | 换算为NM | ||

| 1-64UNC | 0.0538 | 150000 | 0.165 | 3.85 | 0.44 | 2.31 | 0.26 |

| 1-72UNF | 0.0559 | 150000 | 0.165 | 4.32 | 0.49 | 2.59 | 0.29 |

| 2-56UNC | 0.0642 | 150000 | 0.165 | 6.55 | 0.74 | 3.93 | 0.44 |

| 2-64UNF | 0.0668 | 150000 | 0.165 | 7.38 | 0.83 | 4.43 | 0.50 |

| 3-48UNC | 0.0734 | 150000 | 0.165 | 9.79 | 1.11 | 5.87 | 0.66 |

| 3-56UNF | 0.0771 | 150000 | 0.165 | 11.34 | 1.28 | 6.81 | 0.77 |

| 4-40UNC | 0.0814 | 150000 | 0.165 | 13.35 | 1.51 | 8.01 | 0.90 |

| 4-48UNF | 0.0864 | 150000 | 0.165 | 15.96 | 1.80 | 9.58 | 1.08 |

| 5-40UNC | 0.0944 | 150000 | 0.165 | 20.82 | 2.35 | 12.49 | 1.41 |

| 5-44UNF | 0.0972 | 150000 | 0.165 | 22.73 | 2.57 | 13.64 | 1.54 |

| 6-32UNC | 0.1 | 150000 | 0.165 | 24.75 | 2.79 | 14.85 | 1.68 |

| 6-40UNF | 0.1074 | 150000 | 0.165 | 30.66 | 3.46 | 18.40 | 2.08 |

| 8-32UNC | 0.1259 | 150000 | 0.165 | 49.39 | 5.58 | 29.63 | 3.35 |

| 8-36UNF | 0.1301 | 150000 | 0.165 | 54.50 | 6.15 | 32.70 | 3.69 |

| 10-24UNC | 0.1394 | 150000 | 0.165 | 67.04 | 7.57 | 40.23 | 4.54 |

| 10-32UNF | 0.1519 | 150000 | 0.165 | 86.75 | 9.79 | 52.05 | 5.88 |

| 12-24UNC | 0.1654 | 150000 | 0.165 | 111.99 | 12.64 | 67.19 | 7.59 |

| 12-28UNF | 0.1724 | 150000 | 0.165 | 126.82 | 14.32 | 76.09 | 8.59 |

| 1/4-20UNC | 0.1894 | 150000 | 0.165 | 168.16 | 18.99 | 100.89 | 11.39 |

| 1/4-28UNF | 0.2064 | 150000 | 0.165 | 217.62 | 24.57 | 130.57 | 14.74 |

| 5/16-18UNC | 0.2452 | 150000 | 0.165 | 364.87 | 41.19 | 218.92 | 24.72 |

| 5/16-24 | 0.2618 | 150000 | 0.165 | 444.10 | 50.14 | 266.46 | 30.08 |

| 3/8-16UNC | 0.2992 | 150000 | 0.165 | 662.92 | 74.85 | 397.75 | 44.91 |

| 3/8-24UNF | 0.3243 | 150000 | 0.165 | 844.14 | 95.31 | 506.49 | 57.18 |

| 7/16-14UNC | 0.3511 | 150000 | 0.165 | 1071.19 | 120.94 | 642.72 | 72.56 |

| 7/16-20UNF | 0.3767 | 150000 | 0.165 | 1323.01 | 149.37 | 793.80 | 89.62 |

| 1/2-13UNC | 0.4069 | 150000 | 0.165 | 1667.39 | 188.25 | 1000.44 | 112.95 |

| 1/2-20UNF | 0.4932 | 150000 | 0.165 | 2969.23 | 335.24 | 1781.54 | 201.14 |

| 9/16-12UNC | 0.4617 | 150000 | 0.165 | 2435.87 | 275.02 | 1461.52 | 165.01 |

| 9/16-18UNF | 0.495 | 150000 | 0.165 | 3001.86 | 338.92 | 1801.12 | 203.35 |

| 5/8-11UNC | 0.5152 | 150000 | 0.165 | 3384.56 | 382.13 | 2030.74 | 229.28 |

| 5/8-18UNF | 0.5575 | 150000 | 0.165 | 4288.54 | 484.19 | 2573.13 | 290.51 |

| 3/4-10UNC | 0.6291 | 150000 | 0.165 | 6162.18 | 695.73 | 3697.31 | 417.44 |

| 3/4-16UNF | 0.674 | 150000 | 0.165 | 7578.01 | 855.58 | 4546.80 | 513.35 |

| 7/8-9UNC | 0.7408 | 150000 | 0.165 | 10061.86 | 1136.01 | 6037.11 | 681.61 |

| 7/8-14UNF | 0.7884 | 150000 | 0.165 | 12128.72 | 1369.37 | 7277.23 | 821.62 |

| 1-8UNC | 0.8492 | 150000 | 0.165 | 15156.72 | 1711.24 | 9094.03 | 1026.74 |

| 1-14UNF | 0.9132 | 150000 | 0.165 | 18848.33 | 2128.03 | 11309.00 | 1276.82 |